The Importance of Monitoring Your Cryotherapy Chamber

In today’s digital age, monitoring is crucial for maintaining the smooth operation of Ultra Low Temperature (ULT) chambers and engines that underpin businesses, institutions, and daily activities. Effective monitoring leverages advanced sensors, Network Operating Centers (NOCs), and internet access to prevent down time, enhance performance, and monitor overall health. Here’s a closer look at why cryotherapy chamber monitoring is essential and how these elements work together to keep our ULT device running smoothly.

Understanding Monitoring for your Cryotherapy Chamber

Monitoring involves the continuous observation and analysis of an ULT device as a single unit or in a network to detect and address slow or failing components. The primary goal is to maintain optimal performance and maximize up-time, ensuring that the device(s) operate seamlessly.

The Role of Sensors in Monitoring

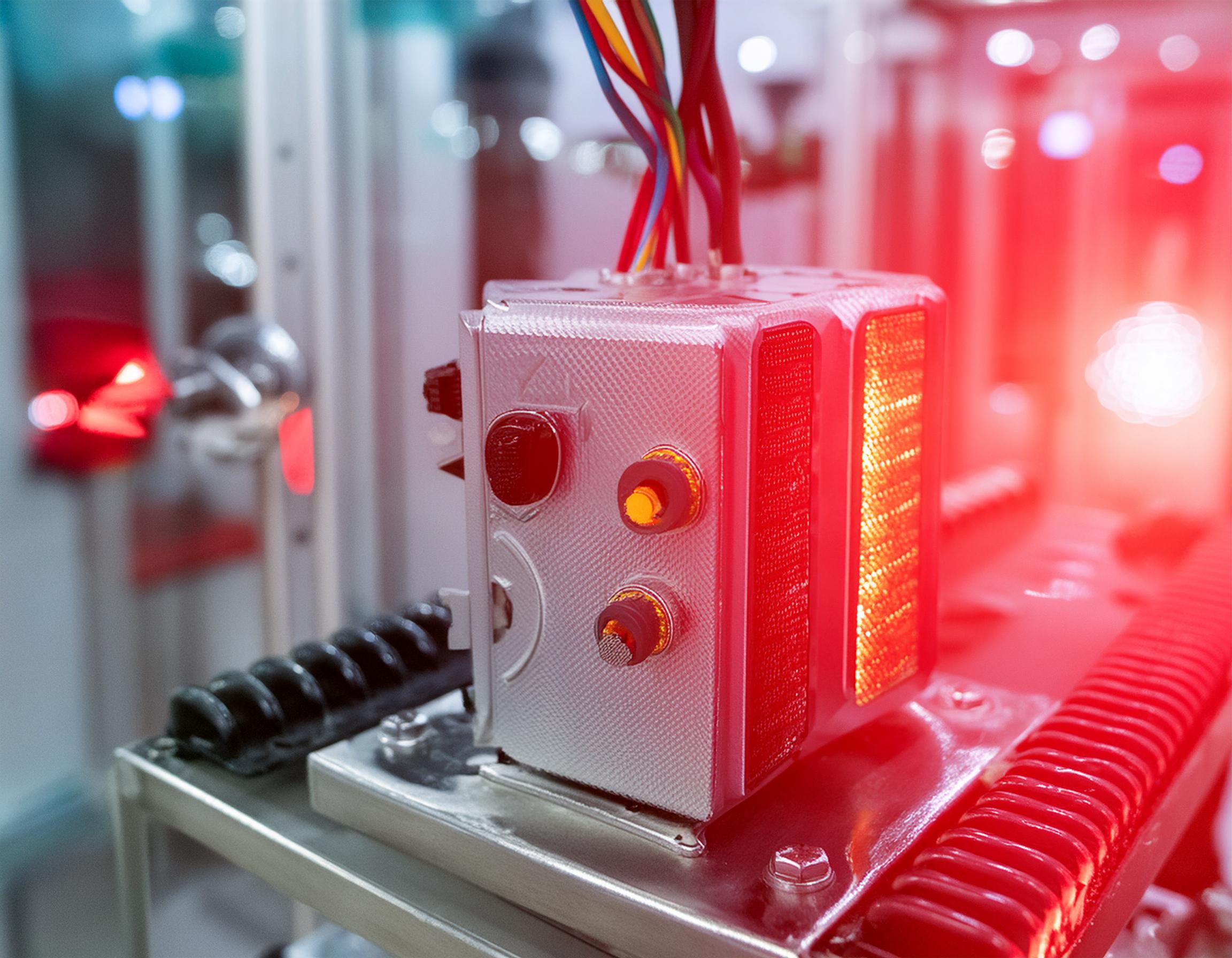

Sensors are fundamental to monitoring. These small devices are strategically placed throughout the ULT devices to collect real-time data on various parameters.

Environmental Sensors

Environmental sensors track the physical conditions of the ULT devices, such as temperature, electricity, RPM’s, and humidity. For instance, if a temperature sensor detects an overheating compressor, it can trigger an alert, allowing technicians to address the issue before it causes hardware failure.

This is a sensor that monitors a compressor in a Cryotherapy Chamber.

Network Operating Centers (NOCs)

A Network Operating Center (NOC) is the command center for device monitoring. It is where IT professionals keep a watchful eye on the device(s) and monitor the network’s health and performance.

Real-Time Monitoring of your Cryo Chamber

NOCs provide real-time visibility into the ULT device status. Technicians use advanced software to visualize data from sensors, enabling them to monitor key metrics and detect anomalies as they occur.

Incident Response

When an issue is detected, the NOC coordinates a swift response. Whether it’s dispatching technicians to address hardware failures, notifying the right personnel or just monitoring that the situation does not get critical. The NOC ensures that problems are resolved quickly and efficiently.

Data Analysis and Reporting on your Chamber

NOC’s analyze historical data to identify trends and potential future issues. This supports predictive maintenance, helping to prevent problems before they occur. Regular reporting provides insights into your cryotherapy chamber device(s) performance, highlighting areas for improvement.

Internet Access and Connectivity

Internet connectivity is the backbone of modern ULT monitoring system, enabling remote access, data transmission, and communication among device components.

Internet access allows monitoring to be conducted remotely. Technicians can access the NOC from any location, ensuring continuous monitoring even outside of regular business hours. This capability is crucial for maintaining a 24/7 operational systems.

Cloud-Based Solutions

Many cryotherapy monitoring tools leverage cloud-based platforms, offering scalability, flexibility, and robust data storage. Cloud solutions enable centralized monitoring and management of dispersed cryotherapy chamber networks, making it easier for a ULT enterprise to maintain consistent performance across multiple locations.

IoT Integration

The Internet of Things (IoT) extends the reach of cryotherapy chamber monitoring by connecting a wide array of devices and sensors to the ULT network. This integration provides comprehensive visibility into device network operations, enhancing the ability to monitor and manage diverse environments, from a single franchise organization to the franchisor that must have visibility into every location is supports.

Personal Insights

From my experience, transitioning to advanced cryotherapy chamber monitoring has been transformative. Manual checks and periodic maintenance used to be the norm, it was time-consuming, but it also left room for missed issues and unexpected down times. Using real-time monitoring and predictive maintenance, we can now address problems before they escalate, saving both time and resources.

I once worked with a team managing a large pharmaceutical network, environmental sensors were particularly beneficial. These sensors monitored temperature and humidity levels in server rooms, ensuring critical healthcare data remained secure and accessible. There was an instance where a sudden spike in temperature was detected in one of the cold rooms. Thanks to the alert from our monitoring system, we addressed the cooling issue promptly, preventing what could have been a catastrophic failure.

Conclusion

Monitoring is essential for ensuring the seamless operation of modern infrastructure. Advanced sensors, Network Operating Centers, and internet connectivity form the backbone of an effective cryotherapy chamber monitoring system. By providing real-time visibility, enabling swift incident response, and leveraging predictive maintenance, these components help maintain optimal cryotherapy chamber performance and security. Because technology continues to evolve, the integration of IoT, cloud solutions, and advanced analytics will further enhance the capabilities of cryotherapy chamber monitoring, ensuring ULT systems remain robust, efficient, and visible in an increasingly connected world.